Malvern Panalytical Molecular Weight Measurement Systems

Malvern Panalytical provides food processing companies with a range of high-quality characterisation tools that are used to optimise product performance through a thorough understanding of materials.

The company’s highly trained staff have expertise in research and development (R&D), materials handling, and testing methodologies, with a thorough understanding of the requirements of large-scale food manufacturing. In addition, the instruments provide a clear indication of the exact ingredients for labelling applications.

Malvern Panalytical is a global company, with sites in North America, Europe, and China. It has strong customer service, helping companies develop expert analytical solutions that deliver superior, actionable insight.

Molecular weight measurement systems

Malvern Panalytical’s range of systems solve analytical challenges, and provides data for optimising products and processes, predicting how products will behave and improves productivity.

Sensory quality, shelf-life, process stability and quality control are important, requiring analytical solutions at many stages.

Malvern Panalytical has systems for rheology, particle size and shape, zeta potential and molecular weight measurement from R&D through formulation to production, quality control and packaging.

Dry food ingredients are often milled to a final size or engineered using processes such as spray drying.

Process particle sizing solutions for optimised milling

Malvern Panalytical offers laboratory and process particle sizing solutions to optimise milling, including Mastersizer and Insitec.

The company also provides Parsum and Insitec solutions for spray drying and Morphologi G3 for particle shape analysers to examine how particles pack.

Malvern Panalytical rheometers are used to examine the rheological behaviour of particles in suspension, to aid formulation of stable products with optimised texture, mouth feel or viscosity.

Gel permeation chromatography is available through Malvern Panalytical’s GPC / SEC, which measures molecular weight and structure of food biopolymers to achieve gelling and thickening performance.

Laser diffraction techniques with Mastersizer and Insitec can avoid over-grinding materials and significant costs.

Rheological instruments for study of additives

Food additives may contain natural or artificial ingredients and include antioxidants, bulking agents, colour, flavour enhancers, emulsifiers, preservatives, stabilisers, thickeners, gelling agents and sweeteners.

Malvern Panalytical’s particle size, zeta potential, imaging and rheological instrumentation are used to study additives and their interaction with food ingredients.

Mastersizer / Zetasizer are ideal for characterising particle size and charge.

In addition, the emulsion stabilisation of flavourings can be improved using Mastersizer / Zetasizer.

Optimising the formulation of spreads

Spreads and sauces, such as mayonnaise, margarine and ketchup, are generally dispersions of an insoluble solid or liquid phase, most commonly in water.

Both spreads and sauces have complex rheological properties, and contain ingredients that must be formulated to produce a stable product with required sensory and nutritional properties.

Malvern Panalytical’s analytical instruments and application solutions can reduce formulation time, ensure formulation stability and verify product properties.

The instruments also optimise manufacturing conditions, monitor quality, ensure regulatory compliance and benchmark products.

Emulsion-based drink formulations

Formulation of any flavour or colour emulsion can be optimised by modifying at particle size and charge, which influences its appearance and stability in final use.

The structure of foams such as beer heads can be evaluated using rheology.

Mastersizer / Zetasizer increases shelf-life through the optimisation of formulations. The instruments also aid understanding about how particle size may change over time, reducing sedimentation or creaming in the product.

Sugar crystals may be an issue in some flavourings and size analysis can detect outsize particles before a problem occurs.

Chocolate consistency, quality control, and cost-efficient production

Understanding, monitoring and controlling particle size and shape in chocolate production ensures a consistent, high-quality production, as well as managing the flow and rheological properties.

Malvern Panalytical’s analytical solutions for size, shape, and rheology improve the chocolate manufacturing process. The solutions are used to monitor the quality of incoming raw materials, optimise grinding, blending, conching and tempering processes.

The instruments improve product quality and performance, minimise process downtime, increase productivity and yields to ensure brand consistency.

About Malvern Panalytical

Panalytical was formed by a merger between businesses Malvern Instruments, PANalytical, ASD, and Claisse in January 2017.

The company employs more than 2,000 highly trained staff, which are experts in research and development (R&D) and manufacturing. Malvern Panalytical is a global company, with sites in North America, Europe, and China. It has strong customer service, helping companies develop expert analytical solutions.

Products and Services

Material Characterisation Solutions for Dry Food Ingredients

Dry food ingredients are available in different forms, and are either milled to a final size or created to be a certain size using a process such as spray drying.

Material Characterisation Solutions for Food Additives

Food additives preserve flavour, enhance taste and appearance, as well as slow spoilage.

Optimising Coffee Taste Using Ground Particle Size Distribution Measurements

The particle size of coffee grounds affects its flavour. If the coffee grind is fine, a powerful espresso flavour may be produced as complex organic components within the bean are released during brewing.

Zetasizer AT Nanoparticle Characterisation System

Malvern's Zetasizer AT brings the industry-leading dynamic light scattering (DLS) technology of the Zetasizer Nano to the process development and manufacturing arena, enabling real-time monitoring of nanoscale particle processes online.

Characterisation of Emulsion-Based Drink Formulations

The formulation of flavour or colour emulsion can be improved by analysing the particle size and charge as this will influence its appearance (cloudiness) and its stability in final use.

Managing the Flow and Rheological Properties of Chocolate

Chocolate taste and texture are important for the consumer, while the manufacturer requires product consistency, quality control and economical production to maintain brand reputation.

Video

Malvern

This video is about the products that Malvern provides.

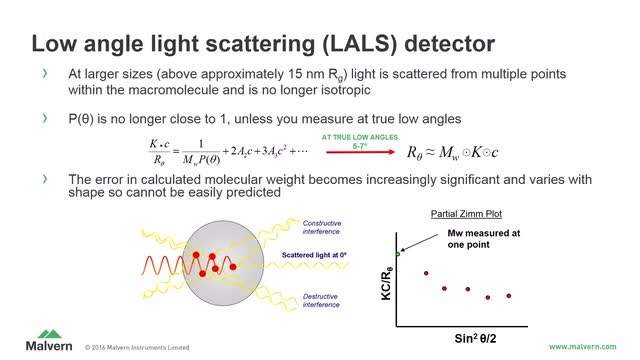

Introduction to Gel Permeation Chromatography (GPC) in 30 minutes

This presentation provides an overview of gel permeation chromatography (GPC), including what it is and some common applications.

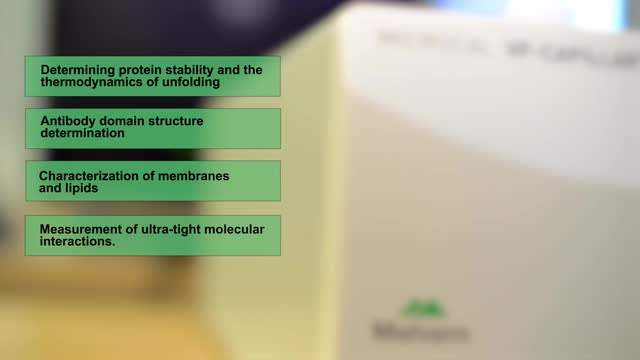

Using Differential Scanning Calorimetry (DSC) to understand the stability of proteins

Differential Scanning Calorimetry (DSC) has a wide application in protein engineering, rational drug design, and biopharmaceutical production where developing stable proteins is a critical goal.

White Papers

Battery Research and Quality Control Solutions

The age of the battery is well underway.

Particle Morphology of Wheat Flour and Gluten-free Flour: Characterisation of Starch and Protein Using MDRS

Wheat flour is expected to reach a global production level of 411 million metric tonnes by 2024, translating to a value of $206bn, based on an average global price of $0.5/kg.

The Analysis of Pressed Powdered Dairy Samples

The analysis of pressed powdered dairy samples (whole and skimmed milk powder, milk protein, whey powder, cheese powder, infant formulas, etc.) by XRF spectrometry faces two major challenges: the inherent small-scale heterogeneity from many of those materials and the high fat content that may be present.

How to Analyse Chocolate Rheology With ICA Method 46 and the Casson Model

Of high importance for both the sensory characteristics (texture) and processing of chocolate is its rheology or viscosity, which is influenced by multiple factors, including particle characteristics such as size and shape, fat composition and structure.

NIR and Dairy

ASD optical spectrometry instruments are a practical solution for the determination of dairy composition measurement and property analysis opportunities.

Understanding Yield Stress Measurements

The yield stress characteristic is a property associated with numerous types of complex fluids, where the material does not flow unless the applied stress exceeds a certain value. This is evident in everyday tasks such as squeezing toothpaste from a tube or dispensing ketchup from a bottle.

Related Projects

Press Release

A list of live webinar events that Malvern Panalytical will be hosting over the next few months.

Read moreBelow follows a short update to let you know what Malvern Panalytical is doing to help you and ensure that business continues as normally as possible during the Covid-19 pandemic.

Read moreMalvern Panalytical understands that the data our analytical systems provide to our customers is critical for informing the development of new products or for ensuring product quality is maintained during manufacture.

Read moreMalvern Panalytical will be hosting or attending a number of events in the upcoming months.

Read moreMachinery and instrumentation specialist NETZSCH proudly announces the extension of its product portfolio with the Kinexus rotational rheometers and Rosand capillary rheometers previously manufactured and supplied by Malvern Panalytical Limited.

Read moreMany people, even those that are not vegan, are increasingly using substitute products in our diets.

Read moreOver the next few months, Malvern Panalytical will be hosting and attending a number of events.

Read moreOn 7 November 2019 Malvern will hold a webinar event titled 'Focus on Food - Coffee Characterisation'.

Read moreIn 2016, Metals and Additives LLC, a leading manufacturer and supplier of powder additives for the battery and plastics industries, purchased the Mastersizer 3000 from Malvern Panalytical.

Read moreThe cornerstones of battery performance are power, which impacts current and discharge characteristics, and energy storage capacity.

Read moreASTM International has announced that it will hold a board meeting and other related events in Boston, Massachusetts, US this October 13 - 16.

Read moreThe New Model in Technology and Engineering (NMiTE) has announced three appointments to its Board of Trustees.

Read moreMalvern Panalytical has announced its next round of webinars. Find out more below. If you are interested in attending any of these events, please send an enquiry to find out how to register.

Read moreMalvern Panalytical has announced the next wave of webinars, seminars and conferences for June.

Read moreThe next generation of Epsilon 1 X-ray fluorescence (XRF) spectrometers has been launched today by Malvern Panalytical.

Read moreMalvern Panalytical has announced the next set of webinars for the November and December period, including a particle size masterclass, ‘Using Rheology to Characterise Asphalt for Roofing Applications’ and 'Major Advancement in the Elemental Analysis of Metal Sulfides'.

If you are interested in attending any of these events, please make an enquiry using the form on this page.

Read moreMalvern Panalytical has announced its latest set of seminars for the November/December period, including a NanoSight workshop, an OMA user day and a DLS Workshop.

Read moreMalvern has announced a series of seminars taking place throughout September and October. If you are interested in attending any of the events and have any questions, please make an enquiry using the form on this page.

Read moreMalvern Panalytical has released information about its upcoming webinars.

Read moreMalvern Panalytical presents its latest upcoming webinars and seminars.

Read moreMalvern Panalytical has announced a wide range of upcoming webinars throughout July, including ‘Enter a New Dimension of X-Ray Diffraction Analysis’ and ‘Applications of Light Scattering and Intrinsic Viscosity Detectors with Size Exclusion Chromatography SEC in Characterising Biopharmaceutical and Other Polymers’. To register for any of these webinars, please either make an enquiry using the form on this page or visit www.malvernpanalytical.com/en/learn/events-and-training/webinars.

Read moreThis year’s European Powder Diffraction Conference (EPDIC16) is the stage for Malvern Panalytical’s new Empyrean platform, an instrument that redefines the concept of multipurpose X-ray diffraction.

Read moreThe new and upcoming seminars from Malvern Panalytical include ‘One-on-One Breakfast Catch-up on the Latest Powder XRD’ and ‘XRF Demonstration (Singapore)’.

Read moreMalvern Panalytical’s webinars in June include ‘A Basic Introduction to Rheology and Rheometry – Part Two, Viscoelectricity’ and ‘Enter a New Dimension of X-ray Diffraction Analysis’.

Read moreMalvern Panalytical has announced the release of its new Zetasizer® Pro and Ultra systems.

Read moreMalvern Panalytical has announced it will be hosting a range of webinars this month.

Read moreMalvern will be hosting a range of webinars in April.

Read moreThe new Morphologi® range of automated static imaging systems for particle characterisation from Malvern Panalytical has been unveiled. The new range includes the Morphologi 4 and Morphologi 4-ID.

Read moreMalvern has announced it will be holding a new webinar to explain the use of electrophoretic light scattering (ELS) to measure the electrophoretic mobility of particles or molecules in a solution.

Read moreMalvern Panalytical presents Epsilon 4, the new high-performance benchtop analytical tool for the determination of the chemical composition of all kinds of material.

Read moreSometimes referred to as photon correlation spectroscopy or quasi-elastic light scattering, dynamic light scattering (DLS) is a technique classically used for measuring the size of particles typically in the sub-micron region, dispersed in a liquid.

Read moreMalvern is hosting a webinar to provide an overview of the nanoparticle characterization platform NanoSight NS300.

Read moreMalvern Panalytical has announced the launch of a collaborative project that aims to support the development of existing and next generation biopharmaceutical products.

Read moreSupplier of analytical X-ray instrumentation and software PANalytical has announced the introduction of a new Epsilon 1 X-ray fluorescence (XRF) spectrometer.

Read moreUnderstanding the make-up of crystalline structures is a vital aspect of the characterisation of new compounds, and can be regarded as an important first step towards the possibility of tailoring its properties.

Read moreA new webinar by Malvern evaluates and discusses size-exclusion chromatography (SEC) data to see the impact of different formulations on monoclonal antibodies and biosimilar molecules.

Read moreMalvern presents a webinar discussing the differences between rheometers and viscometers.

Read moreMalvern invites you to register for the food and drink seminar coming to Chicago.

Read moreGuest speakers John F Carpenter and Harald van Weeren to star in Malvern's newest Webinar additions this month: Differential Scanning Calorimetry (Robust and Powerful Physical Characterisation of Therapeutic Protein Products) and Cement (Composition, Structure, and Fineness - We are Stronger Together!).

Read morePacking density and flow behaviour of metal powders has an effect on manufacturing efficiency of powder bed additives.

Read moreMalvern will host a webinar discussing the particle tracking analysis (PTA) method (ISO19430) and what it means for nanoparticle measurements.

Read moreIf you are attending Pittcon this year, why not register for Malvern's short courses, which are taught by recognised characterisation experts.

Read moreMalvern has announced it will be hosting a webinar about the use of laser diffraction as a technique in characterising nebulisers and how it is helpful in understanding the delivery of the drug product.

Read moreMalvern has announced it will host a webinar to discuss how to measure zeta surface potential.

Read moreSize exclusion chromatography (SEC) is a popular analytical technique for studying protein molecular weight, oligomeric state, aggregation, and conjugation.

Read moreMalvern has announced it will host a live-panel webinar for the discussion of challenges submitted in an online form on the company's website.

Read moreMalvern has announced it will be hosting a webinar discussing gel permeation chromatography (GPC).

Read moreMalvern has announced its latest webinar discussing the types of technologies used for analysing particulates in injectable drugs.

Read moreAdvancements in portable electronic devices such as mobile phones and laptops has increased demand for advances in battery technology.

Read moreMalvern has announced it will host a webinar discussing the use of a diffusion interaction parameter (kD) measurement for the Taylor dispersion analysis in early stages of development.

Read moreMalvern has announced it will be hosting a webinar to discuss the rheological requirements of paintings and coatings, as well as how they can be measured using a rotational rheometer.

Read moreMalvern will showcase its new measurer in a desk-demo webinar, demonstrating the Nanoparticle Tracking Analysis (NTA) method.

Read moreMost products go through a stage where different phases co-exist such as emulsions, suspensions, or dispersions.

Read moreMalvern's Morphologi G3-ID system has been used by the Food and Drug Administration (FDA) to generate key data for the approval of the first generic nasal spray containing mometasone furoate.

Read moreMalvern Instruments has launched the new Zetasizer AT, a robust, online, automated analyzer that uses dynamic light scattering (DLS) to automatically measure the size of nanoparticles in suspensions and emulsions.

Read moreMalvern Instruments has extended the application of NanoSight, a nanoparticle characterisation technology with unique capabilities.

Read moreMalvern Instruments and Bio-Rad plan to deliver new analytical tools for the rapid identification of unknown particles.

Read moreInsights shared by Particle Characterization Laboratories director William Bernt recognise the impact of adding a Malvern NanoSight nanoparticle tracking analysis (NTA) system to a toolkit for nanoparticles.

Read moreMalvern will be showing new tools that address specific analytical challenges in biopharma development at this year's AAPS Annual Meeting and Exposition, in Orlando, US.

Read moreInsight from CP Kelco, a global leader in the specialty hydrocolloids market, provides a blueprint for the intelligent, cost-efficient deployment of gel permeation/size exclusion chromatography (GPC/SEC) in biopolymer manufacture.

Read moreMalvern has opened a new biopharmaceutical applications laboratory in San Diego's biotechnology cluster.

Read moreRegional Offices

Enigma Business Park

Grovewood Road

Malvern

WR14 1XZ

Worcestershire

United Kingdom

4995 Levy Street

Montreal

H4R 2N9

Quebec

Canada

Unit 101, XinAn Plaza

Building 13

No 99 Tianzhou Road

200233

Shanghai

China

Korskildelund 6

DK-2670 Greve

Zealand

Denmark

Kumitehtaankatu 5

Klondyke

Kerava

FIN-04260

Helsinki

Finland

Parc Club de l'Université

30 Rue Jean Rostand

Orsay Cedex

91893

Ile-de-France

France

Marie-Curie-Str. 4/1

71083 Herrenberg

Germany

11th floor sector - 30A Opp Vashi Railway Station

Vashi

Navi Mumbai

400 705

Mumbai

India

5-5-2 Minatojimaminami-machi Chuo-ku

Kobe-shi

Hyogo Prefecture 650-0047

Honshu

Japan

16-6 Sunae-Dong

Bundang-Gu, Seongnam-City

Kyeonggi-Do

Seoul

South Korea

Av. De La Industria No 300

San Pedro Garza Garcia

CP 66279

Nuevo Leon

Mexico

Lokkeasveien 22A

Skallestad

N-3138

Vestfold

Norway

Vallongatan 1

Uppsala

752 28

Uppsala County

Sweden

117 Flanders Road

Westborough

MA

01581-1042

Maine

United States of America