Flexco Belt Splicing and Maintenance Solutions for the Food Industry

Flexco manufactures endless splicing and belt cleaning solutions for the food processing industry. The company is an industry leader in maximising belt conveyor productivity with products that set the industry’s highest standards for intuitive design, ease of installation and maintenance, and durability.

Minimising downtime with effective solutions

Food processing operations around the globe choose Flexco products for their endless splicing and belt cleaning needs.

Air-cooled endless splicing equipment

A major pain point for those who maintain their conveyor belts is that most are bulky and take a long time to set up and tear down.

Water-cooled presses rely on external components and a water source to be filled on site. That is what makes the Novitool® Aero® Press an endless splicing solution that surpasses the rest.

- Fast cycle time: The Novitool Aero Press is able to complete a cycle in 7 to 12 minutes, which can save approximately 40 minutes every time a splice is needed.

- Lightweight design: Portability is a key consideration when choosing a press. The Aero Press weighs nearly 60% less than conventional presses and comes with a portable rolling storage case.

- Few external components: The Aero Press has built-in compressors and cooling systems, so the only extra component is a single, electrical cable. The quick setup and cleanup can save an additional 20 minutes off the total splice time.

- Voltage versatility: The Novitool Aero Press can be used with 230V single phase, 230V three-phase, 400V three-phase +N, and 460V three-phase power sources by changing the power cord.

- Air-cooling technology: The Aero Press has a press with a built-in, air-cooling system, eliminating waterborne safety and hygiene issues presented with traditional water-cooled presses.

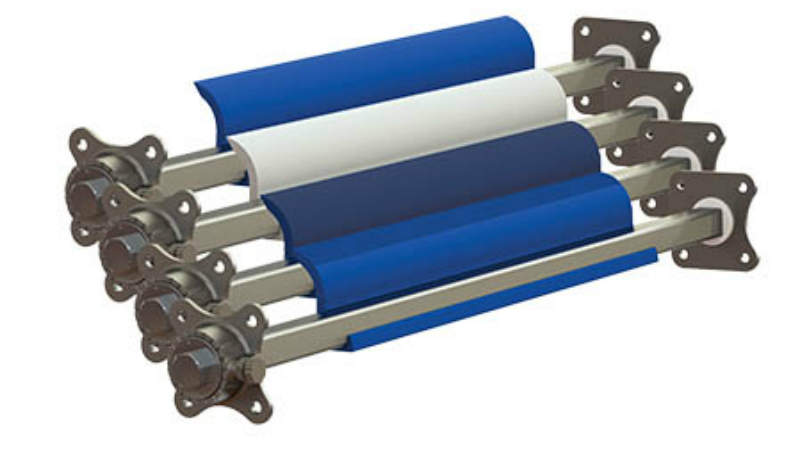

Engineered light-duty belt cleaners

Carryback occurs when product travelling on the conveyor belt sticks to the underside of the belt instead of being removed by cleaning or falling off the belt.

When not managed appropriately, loss of product, excessive downtime, and cleanup costs are just some of the problems that occur. Less common, but as important is the possibility of product contamination or sizable fines resulting from regulatory non-compliance.

The FGP Food Grade Precleaner from Flexco is an engineered solution designed for ease of use, including quick disassembly (under a minute) for sanitisation. The FGP is crafted using only FDA-approved materials and is designed using only rounded interior angles to make sanitation easier with minimal crevices to harbour bacteria or other contaminants.

The FGP’s quick disassembly/reassembly helps reduce the time spent maintaining the belt, as well as the overall cost associated with it.

The FGP Precleaner from Flexco is engineered with a simple-to-adjust spring tensioning unit that ensures optimal blade-to-belt contact. In addition, the blade snaps off and back into place, reducing the time it takes to clean or replace the blade.

Certified equipment eases compliance

Employing certified equipment, such as the USDA-certified FGP Food Grade Precleaner from Flexco, can assist operations in reaching compliance with Food Safety Modernization Act regulations, which eases the regular inspection process and may reduce liability.

Products and Services

Alligator® Staple Fastening System

The Alligator® Staple Fastening System is ideal for a wide variety of light-duty and medium-duty fastener applications.

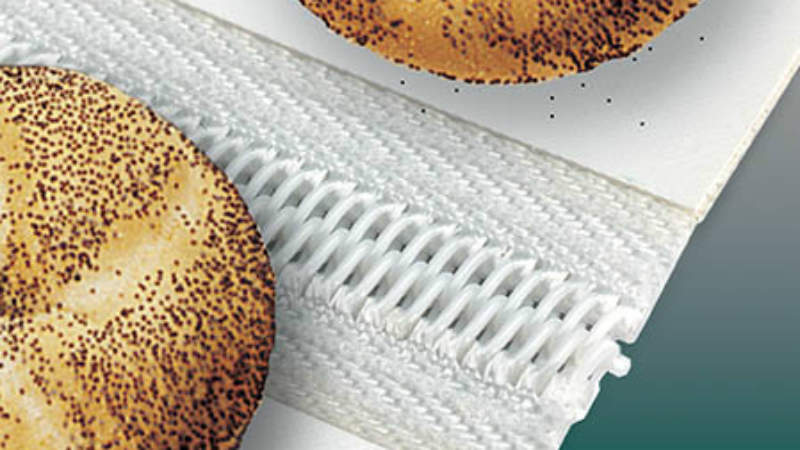

Alligator® Spiral Lace Fastening System

The Alligator® Spiral Lace Fastening System is ideal for belt operations with small head pulleys that require both non-metallic and low-profile fasteners.

FGP Food-Grade Precleaner

The FGP Food-Grade Precleaner meets the high standards of the food processing industry. It is easy-to-install, easy-to-maintain, and disassembles in a snap for regular cleaning and sanitisation.

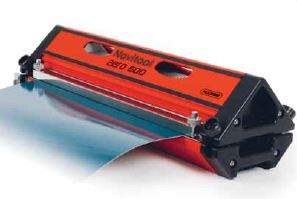

Novitool® Aero® Splice Press

The Novitool® Aero® Splice Press offers the latest technology to create a high-quality splice, typically in less than ten minutes. All necessary components are compactly self-contained, making the press easy-to-use, store and transport.

Novitool® Ply 130™ Ply Separator

The Novitool® Ply 130™ Ply Separator cuts between the plies of conveyor belting for belt splice preparation. Plies can be split as deep as 5in (130mm) in one action, making the tool perfect for preparing stepped splices and for recessing mechanical fasteners.

Video

White Papers

Adding up the True Cost of Your Homemade Conveyor Belt Cleaner

The FGP Precleaner is engineered with a simple to adjust spring tensioning unit that ensures optimal blade to blade contact.

How to Limit Downtime in Your Food Processing Plant

Many food processing facilities use outside contractors to splice conveyor belts, but this isn't the most productive way to get your belt conveyor system back up and running quickly.

Related Projects

Press Release

Flexco and MLT Minet Lacing Technology announced today that they have signed an agreement in which Flexco will be the exclusive source for MLT products in the US, Canada, and Mexico.

Read moreFlexco has announced that its facility in Grand Rapids, Michigan, will be expanding its operation and relocating to a new location.

Read moreFlexco has announced its plans to exhibit at this year’s International Baking Industry Exposition (IBIE).

Read moreIf you’re using an outside crew to install endless splices on your conveyor belts, there are a few steps you have to take the minute you realise the belt needs to be fixed.

Read moreFlexco has announced plans to exhibit at PROCESS EXPO.

Read moreFlexco celebrated reaching 110 years in business with worldwide special surprises, giveaways, site luncheons, and days where employees were encouraged to wear Flexco gear

Read moreWith state-of-the-art technology, Novitool® Aero® Splice Press uses Flexco's exclusive Aero Recipe Management Tool for consistently high-quality splices.

Read moreThe online training tool of Flexco University has been launched, featuring three levels of courses, quizzes, and the capacity of running training groups.

Read moreFlexco recently unveiled an expanded training facility dedicated to the education of its customers and employees.

Read moreFlexco has announced its plans to exhibit at this year's International Production and Processing Expo (IPPE).

Read moreFlexco has added to its line of endless splicing solutions the Novitool Amigo for splicing monolithic belts.

Read moreFlexco has introduced the Novitool Aero portable splice press.

Read moreFlexco is proud to introduce the FGP Food Grade Precleaner to its line of light-duty belt conveyor products.

Read moreRegional Offices

2525 Wisconsin Avenue

Downers Grove

60515

Illinois

United States of America