NETZSCH Pumps & Systems Experts in Industrial and Hygienic Positive Displacement Pump Solutions

NETZSCH Pumps & Systems has been manufacturing positive displacement pumps to a worldwide client base for more than 60 years.

Specifically designed for a variety of pumping applications, NETZSCH’s products range from small metering pumps to high volume pumps and are used in demanding applications across many industries.

NEMO® progressing cavity pump

In 1951, NETZSCH Group began manufacturing and distributing positive displacement pumps with its flagship NEMO progressing cavity pump, which was designed according to the Moineau pump system. The NEMO pump took the first half of its name from ‘NETZSCH’ and the second half from ‘Moineau’.

The NEMO progressing cavity pump is used in the food, pharmaceutical, cosmetic and chemical / biochemical industries for hygienic applications and optimal cleaning. It is ideal in these settings due to its continuous, pressure-stable, gentle and low-pulsation conveyance and its capability of dosing in proportion to speed. The block pump construction with flanged drive is very compact and economical to operate.

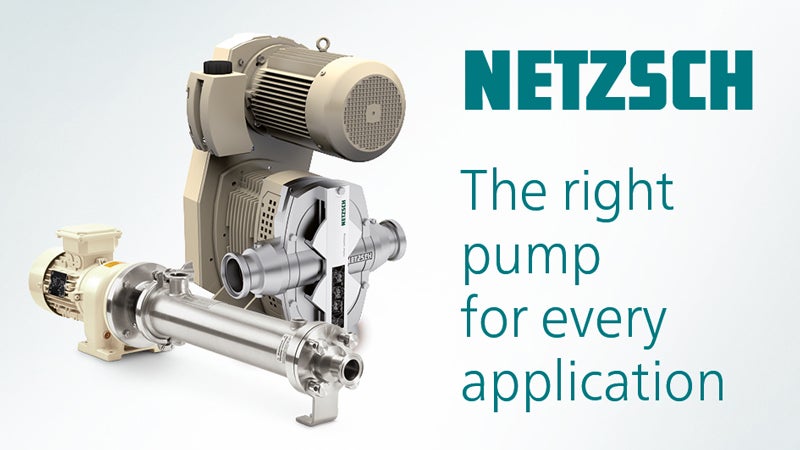

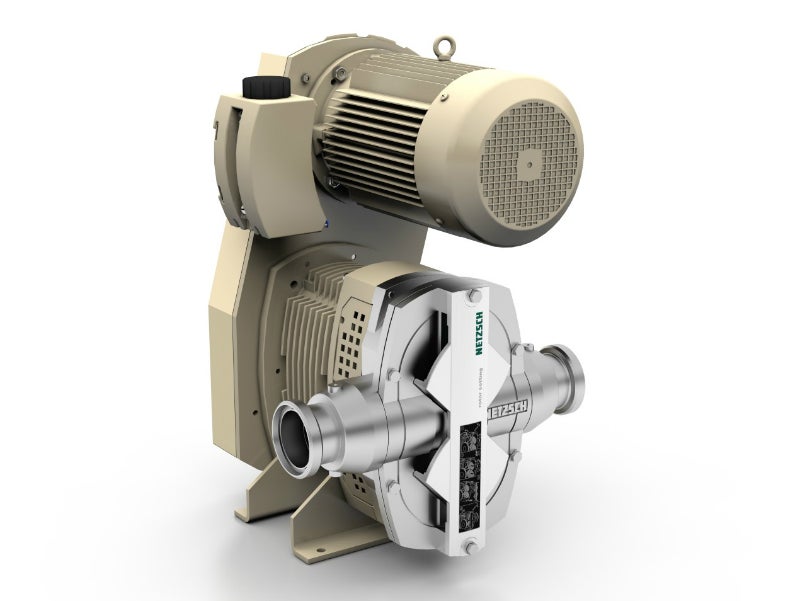

TORNADO® rotary lobe pumps

In 2002, NETZSCH began developing and manufacturing its successful range of TORNADO rotary lobe pumps. TORNADO pumps are used in a constantly growing number of applications for continuous and gentle conveyance of substances.

T2, the second generation of TORNADO, was introduced by NETZSCH in 2012. Its new design completely revolutionized the performance of the rotary lobe pump.

NOTOS® multi screw pumps

One of the company’s most recent pump innovations involved the development of the NOTOS multi screw pump in Brazil. NETZSCH has been selling these products on a global basis since 2014.

The products can be used for various applications, with the range consisting of three design series with two, three and four screws.

Waste water treatment and biogas technology

The ‘Environmental and Energy’ business field of NETZSCH Pumps & Systems is an industry leader in the treatment of waste water and biogas technology.

NETZSCH Pumps & Systems ‘Environmental and Energy’ delivers positive displacement pumps as conveying systems for all environmental technology processes and demands. As a result of the pumps’ regulating characteristics, they ensure a safe, reliable and efficient operation.

From NEMO progressive cavity pumps to TORNADO rotary lobe pumps or NOTOS multi-screw pumps, NETZSCH conveying systems have been used across many industries, such as agriculture, waste water cleaning, water purification, renewable energy, construction, electroplating and marine.

About NETZSCH

Founded in the German city of Selb in 1873, The Gebrüder NETZSCH Maschinenfabrik (NETZSCH Brothers Machine Works) became the starting point for the current NETZSCH Group. While remaining a family-owned business with headquarters in Selb, NETZSCH now employs more than 3,500 employees across 210 global locations over five continents and is made up of three distinct business units.

Manufacturing over 55,000 high-quality pumps each year, the NETZSCH Pumps & Systems business unit has built up a market leader reputation due to its core competence and vertical integration.

The company provides its customers with reliable systems from each of its five production sites, implementing the highest standards in accordance with DIN EN ISO 9001.

As well as the NEMO progressing cavity pumps, TORNADO rotary lobe pumps and NOTOS multi screw pumps, NETZSCH supplies macerators / grinders, dosing technology and other equipment custom built to handle challenging applications.

Products and Services

NETZSCH NEMO Barrel Emptying System

NETZSCH Barrel Emptying Systems suction themselves automatically to the bottom of a barrel or container to achieve near residue-free emptying for applications in the cosmetic, pharmaceutical and food industries.

TORNADO® Rotary Lobe Pumps

NETZSCH TORNADO® rotary lobe pumps are highly versatile, stand-alone pieces of equipment.

NEMO® Progressing Cavity Pumps

NETZSCH's NEMO® Progressing Cavity Pumps have an extremely wide application range and are used in all branches of industry for the continuous, pressure-stable, gentle and low-pulsation conveyance of almost any substance.

Video

White Papers

Positive Displacement Pumps for Wastewater Treatment and Biogas Technology

NETZSCH provides positive displacement pumps as conveying systems for all media in environmental technology, specialising in the field of wastewater treatment and biogas technology.

Technology and Applications for Positive Displacement Pumps

For more than sixty years, NETZSCH has been a leading manufacturer of positive displacement pumps for food processing and other applications.

Press Release

NETZSCH is excited to announce the extension of its product portfolio with the Kinexus rotational rheometers and Rosand capillary rheometers formerly manufactured and distributed by Malvern Panalytical.

Read moreNETZSCH has announced it will be presenting its pump solutions at the Hannover Messe 2017.

Read moreNETZSCH has announced it will be present at the Wasser Berlin International in Berlin, Germany.

Read moreStatistics tell us that every German citizen eats around 9.5kg of chocolate a year, in the form of bars, hollow figures, pralines and such like, with a particularly steep rise in consumption at Easter and Christmas.

Read moreAt a brewing company in Pennsylvania in the US, the brewmasters turned to reliable NETZSCH NEMO® progressing cavity pumps for the difficult jobs of moving spent grain and yeast through the brewing process.

Read moreA large wine cellar in the northern-Italian province of Trentino now uses special pumping technology from Germany-based NETZSCH Pumps & Systems. The progressing cavity pump from NETZSCH works exceptionally smoothly, leaving wine unchanged, as tests have demonstrated. At the same time, the technology is so compactly installed that it can be moved wherever needed along with its switch cabinet, so the vintner can work at all tanks with just one pump.

Read moreNETZSCH Pumps & Systems has developed special barrel emptying systems that function as sealed systems, due to a tailored secondary plate, and are sufficiently powerful on the suction side to leave residues of just 1%-2%. In the current reworked version, the entire design has been slimmed down for simpler cleaning and mobility.

Read moreThe new TORNADO® T.Sano rotary lobe pump from NETZSCH Pumps & Systems features a pump chamber made completely from stainless-steel. Simultaneously, the new construction provides for less pulsation and wear. For a large producer of edible oil, a TORNADO® T.Sano rotary lobe pump, together with a measurement cell and control unit, has been installed on a small trolley to enable direct and flexible filling of different types of containers.

Read moreRegional Offices

Geretsrieder Str. 1

84478 Waldkraiburg

Germany

Kwang Klongkum

46/158 Moo 12, Nuanchan Road

10230

Bangkok

Thailand

Lanzhou New and High Technology Industrial Development Zone

No. 506 Liu Jia Tan

Lanzhou 730010

China

4F, Jaeneung Bldg, #1066

Jungang-Ro, Ilsandong-Gu

Goyang

South Korea

Ind.E.Com. Ltda, Rua Hermann Weege

Caixa Postal 51

89.107 - 000 Pomerode / SC

Brazil

Ruko Permata Kota Blok D No 6

Jl. Pangeran Tubagus Angke No 170

14450

Jakarta

Indonesia

Dubai Airport Free Zone

Building 5WA - Office No. 105

PO Box: 54700

Dubai

United Arab Emirates

No 3 Eagle Mini Units

Erf 167 Voorraadskip Avenue

2040 Honeydew

South Africa

119, Pickering Way

Exton, PA 19341 - 1393

United States of America

740 Huronia Road, Unit 10

L4N 6C6 Barrie

Canada

D-G-2A, Jalan PJU 1A/3K,

Taipan 1, Ara Damansara,

47301 Petaling Jaya, Selangor

Malaysia

Plot No. 39, 2nd Street

Spartan Nagar, Mogappair

Chennai 600 037

India