Hiperbaric High-Pressure Processing (HPP) Equipment for the Food and Beverage Industry

Hiperbaric provides a highly comprehensive and technically advanced range of high-pressure processing (HPP) units for applications in the food and beverage processing industry.

The company’s intensive R&D, combined with an outstanding team of professionals, has prompted Hiperbaric to a leading position (more than 60% market share), with 300 machines installed worldwide.

HPP units for better products

HPP is a food and beverage non-thermal preservation technology that applies high hydrostatic pressure for some seconds or minutes to packaged products (In-Pack) or beverages before bottling (In-Bulk).

HPP advantages include:

- Premium quality: sensorial, nutritional and functional properties are preserved for up to three months in refrigerated conditions.

- Brand protection: HPP ensures food safety reaching 5-log reduction of pathogenic microorganisms.

- Market expansion: HPP extends shelf life up to ten times larger, allowing the positioning of innovative products in new markets around the world.

- Food environmental sustainability: HPP does not generate effluents and water used to rise pressure can be reused between cycles.

- Highly versatile technology: it can be applied to a wide range of foods: juices and beverages, meat, fish and shellfish, fruits and vegetables, dairy, and ready-to-eat products.

Advantages of In-pack HPP units

- Versatile design: intensifiers (high-pressure pumps) can be installed alongside the machine or in a service corridor and also in a platform on top of the vessel. This last design reduces the footprint and facilitates its implementation in a food industrial environment.

- Wide range of industrial machines: from 55l to 525l, Hiperbaric’s HPP machines meet the requirements of start-ups, small-medium enterprises and large corporations.

- Labour saving and greater flexibility: HPP units are integrated with their own loading and unloading lines and systems. Some suppliers, including Hiperbaric, provide further turnkey automation solutions adapted to customer needs.

- Aftersales service and support worldwide 24/7: highly specialised field technicians, diagnostic services and remote monitoring, after sales portal. All is customer-oriented to satisfy requirements.

- Green technology: it is an environmentally friendly process because HPP machines only need water (which is recycled) and electricity.

Advantages of In-bulk HPP units

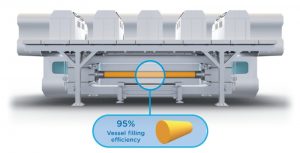

Hiperbaric has recently developed the 525 Bulk, a breakthrough technology for the beverage industry of the future. The beverage is processed into a bag hosted inside the vessel, occupying 90% of the total volume, which is roughly double the one achieved with In-Pack HPP units. Hiperbaric, a global leader in HPP technology, is the only supplier of this breakthrough technology.

Furthermore, In-Bulk HPP units fit perfectly into any large beverage production line and allow the use of any kind of packaging after HPP, no matter the material, design or size. There are large packaging options (bottles, bags, pouches, tubs, trays, vacuum / skin packaging, modified atmosphere packaging), but the units are limited to polymeric flexible packaging. Hiperbaric has revolutionised the HPP industry with the ‘In-Bulk’ processing concept.

This innovative technology reduces steps, simplifies the process and shows high levels of productivity, along with low processing costs and minimum energy consumption.

About Hiperbaric

With headquarters located in Spain, Hiperbaric offers a complete service around the world from its delegation in Miami and Singapore.

Since its inception in 1999, Hiperbaric has designed, developed, produced and marketed its high-pressure processing equipment internationally, with hundreds of clients around the world. Its leadership is based on its fully integrated service that encompasses all stages in the value chain, from production to installation, including a 24/7 aftersales service and a highly qualified team of HPP PhDs that assist the client in any aspect related with the product.

Hiperbaric offers the widest throughput range of industrial HPP machines, meeting the requirements of start-ups, small-medium enterprises and large corporations. Among them, the Hiperbaric 525 model is one of the biggest and most productive HPP systems on the market, delivering more than 6,660lb/h with low processing costs. All the units reach up to 6,000bar / 600MPa / 87,000psi.

The horizontal layout and ergonomic design of all Hiperbaric equipment simplifies installation and operations. Intensifiers (high-pressure pumps) can be installed alongside the machine or in a service corridor. It is also possible to set up the Hiperbaric machines in an integrated configuration, where the intensifiers are installed in a platform on top of the equipment. This design reduces the footprint and facilitates its implementation in a food industrial environment.

Products and Services

Hiperbaric 55 In-pack

The Hiperbaric 55 is the perfect first step into the HPP business with its 55l (14.5 gallons) vessel and a 200mm (7.9in) diameter.

Hiperbaric 135 In-pack

The Hiperbaric 135 is targeted for medium food production.

Hiperbaric 300 In-pack

The Hiperbaric 300 has historically been the most suitable option for medium-high productions, delivering 1,410kg/h (3,100lbs/h).

Hiperbaric 420 In-pack

The Hiperbaric 420 is one of the best-selling HPP machines in the market.

Hiperbaric 525 In-pack

The Hiperbaric 525 is our largest in-pack unit, following the demands of customers with the largest production environments.

Video

White Papers

Hiperbaric Bulk Technology

Hiperbaric Bulk Technology is a global innovation for large production of HPP beverages.

Industrial High-Pressure Processing Systems

Hiperbaric industrial high-pressure processing (HPP) units are designed to be the most reliable systems in the market.

Related Projects

Press Release

The awards are to recognize the scientific contributions of young researchers in high-pressure processing for food.

Read moreHigh-Pressure Processing for Avocado Products: Shelf-life Extension, Clean Label and Premium Quality

High pressure processing (HPP) is the only non-thermal preservation technology for avocado products that meets the high-standard requirements of both consumers and manufacturers: premium quality, clean label, safety, and extended shelf-life.

Read moreCalavo Growers, a leading global avocado and guacamole producer, has acquired Hiperbaric’s 300th high pressure processing (HPP) machine, to be installed in Mexico.

Read moreHiperbaric works in the search of innovative industrial solutions, which immerse food businesses in the riveting world of HPP technology.

Read moreRegional Offices

Polígono Industrial Villalonquéjar

C/ Condado de Treviño, 6

09001

Burgos

Spain

2250 NW 84th Ave Unit 101

Miami

33122

Florida

United States of America