Munters Energy Efficient Air Treatment for the Cold Chain

Munters’ air treatment technology allows for the precise control of temperature and humidity in the food industry cold chain.

It modifies conditions to convey, cool, freeze, dry and cure foods, right through to packing and storage. This guarantees consistent quality, energy cost savings and increased throughput.

Munters designs and manufactures products for controlling moisture, humidity and condensation, while optimising conveying, mixing, blending, drying, cooling, packing and general storage applications.

Dehumidified air combats mould growth and increases refrigeration efficiency. Through frost-free cooling, dehumidification and humidity control, Munters prevents products gaining moisture, sticking and creating costly quality, hygiene and wastage issues.

Air treatment systems for the food industry cold chain

Munters manufactures air treatment systems that eliminate moisture absorption, condensation, product sticking, caking, mould, frost build up and blocked machinery.

From cutting, conveying, freezing, cooling and cold storage through to product conditioning, transportation and storage, Munters provides significant cost savings and quality improvements by mastering the temperature and humidity of the air during transportation and storage.

Munters air treatment systems also control air quality surrounding the production process. Its patented innovative air treatment systems give faster productivity within food processing, reduce accidents and waste in storage and reduce energy consumption.

Munters ICE-DRY®, a simple solution for ice and condensation prevention

Munters Ice-Dry® desiccant dehumidifier prevents condensation and ice build-up, providing higher production rates and reduced downtime caused by icing.

Freezing equipment is designed for a specific level of production and frost on evaporators impedes and interrupts extended operation. It becomes difficult to maintain the temperature inside the freezer, making it necessary to either defrost or lower the rate of throughput to achieve correct freezing temperatures.

Ice build-up on conveyor belts and cooling coils comes from surrounding air leaking into the freezer, as well as moisture evaporating from the product. Dehumidification practically eliminates frost build-up, resulting in reduced defrosting cycles and spoilage, uninterrupted production and higher profits.

With Munters Ice-Dry® humidity control, mould growth is reduced and sanitation improved.

Keeping cold-store floors and doors dry and ice-free

It is impossible to prevent air from entering a cold store, but Munters Ice-Dry® dehumidification removes the moisture in the air that forms ice. Condensation also causes fog around doorways, blinding strip curtains and obstructing views in traffic ways.

Apart from safety issues, ice also prevents the free operation of cold store and airlock doors, preventing them from sealing properly, or even lifting them out of their runners. Smooth operation requires people to regularly chip away the ice by hand, a time-consuming job.

The ice also affects the efficiency of the refrigeration system, increasing defrost cycles and degrading temperature control. All air holds water; warm air holds more water than cold air. This is why water condenses out on cold surfaces and forms ice and frost. Munters tackle the cause of the problem by removing the moisture from the air, so it can’t condense out and form ice on cooling coils, floors, walls or airlocks.

Increased freezer production

Munters Ice-Dry® dehumidification reduces maintenance on doors and refrigeration machinery, reduces downtime, speeds-up loading and unloading and increases efficiency and throughput.

By removing the moisture that normally condenses on evaporating coils, the coils run more efficiently and much longer between defrosts. One cold-store using Ice-Dry® saved €16,000 in 8 months through increased energy efficiency.

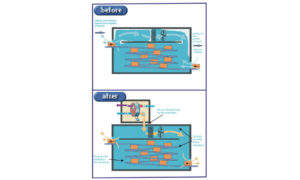

As humid air infiltrates into air-locks and cold-stores through dock doors, Munters Ice-Dry® dehumidification captures it and removes the moisture before it condenses onto cold surfaces.

Dehumidification for increased refrigeration efficiency

As the humid air passes through the Munters Ice-Dry® humidity control system, the moisture is removed and the dry air is returned into the area, flowing across the cold store doors and floors at the rear of loading docks, providing the driest air to the coldest surfaces.

This dry air keeps surfaces free of ice build-up and rapidly removes condensation. This gives quality, productivity and energy savings by simply mastering the relative humidity of the air.

With more than 440 Munters Ice-Dry® humidity control systems installed and over 28 offices globally, we have excellent know-how and the capability to supply complete dehumidification climate solutions.

Products and Services

Condensation and Moisture Absorption

Moisture absorption can affect final product quality and shelf life.

Cooling and Freezing

Munters’ award-winning IceDry technology combats condensation and icing in cooling tunnels, freezing chambers and around cold store entrances, walls and ceilings.

Drying and Coating

Drying and coating processes can be shortened and made more consistent by adding Munters dry air treatment systems.

Energy Efficient Air

Munters’ indoor climate solutions control the environments within offices and whole production areas.

Video

White Papers

Dehumidification in the Dairy Industry

For most companies, the dry winter climate is preferable to the humid summer climate when comparing operating conditions. In wintertime, the drying process is faster and the risk of mould is reduced. Condensation and even ice build-up on cold surfaces is less.

Cooling Tunnel Solution for Confectionery Products

The vast majority of confectionery products are cooled in a tunnel during production. During this cooling process, condensation may occur causing sticking, crystallisation and discolouration of products.

Tastier Lettuce with Munters

Munters develops and manufactures dehumidifiers for the food industry that control the effects that humidity can cause in production processes.

Maximise Your Powder Production

The sale prices of powders are getting increasingly higher. Production tools cost more, so it is now more than ever necessary to maximise the production of your atomising tower and fluidised bed.

Better, Faster, Longer-Lasting Quality and Productivity in Confectionery

Confectionery products such as hard candies, biscuits, chocolates, jellied items, sugar-coated drops or tablets, sugar and popcorn are sensitive products that often lose quality and shelf life when they come into contact with air humidity that is too high.

High Quality Air for High Quality Food

As one of the world's largest suppliers of desiccant dehumidifiers and air handling solutions, Munters has an extensive experience as to techniques to fully control climate conditions.

Quality and Productivity in Confectionery Production

Confectionery products include sensitive products, hard candies, biscuits, chocolates, jellied items, sugar-coated drops or tablets, sugar and popcorn. These items often lost quality and shelf-life when they come into contact with air humidity that is too high.

Storage and Transportation of Powders

Caking of powders and granules is a frequent problem in the food and chemical industries leading to halts in production and product losses.

Increased Productivity in Spray Drying Applications

In the operation of spray drying towers, there are seasonal variations in their operation. In summer months, when the moisture content in the air is high, the operating conditions are less advantageous than in winter months, when the water content is low.

Dry Air Helps Sausages Mature Faster

The process of manufacturing meat products consists of various specific steps combined in such a way that unique products are obtained with characteristic ingredients and flavours.

Related Projects

Press Release

Foodstuffs are perishable goods, whether they’re raw, baked or frozen. If the surrounding climate is not appropriate they become sticky, lumpy, mouldy or discoloured. Quality suffers, leading to lost production, stoppages or spoilt products.

Read moreRiverside Bakery in the UK is a major manufacturer and supplier of chilled quiche products to Sainsbury’s and Marks and Spencer Supermarkets.

Read moreWith almost 2,000 employees, Kraft Foods Nordic is one of the leading Nordic suppliers of chocolate, snacks, food and coffee with brands such as Marabou, Daim, Japp, Twist, Kraft and Philadelphia.

Read moreTyneside Foodservice is one of the largest independent frozen and chilled food wholesalers in the north of the UK, supplying meat, poultry, pastries and savoury products to caterers across the region.

Read moreConfremar in Madrid manufactures and distributes frozen products. The company's lines include frozen fish, shellfish, pre-cooked products and vegetables. The key to its success was to convert a craftsmanship activity into an industrial process without losing the care and quality.

Read moreDry air from Munters dehumidifier enables Danish fish slaughterhouses to fulfil strict demands from authorities.

Read moreBased in Congrella, Durban, KwaZulu-Natal, South Africa, Chester Wholesale Meat was founded 25 years ago and has grown to provide packaged and processed meat and poultry products to markets wordlwide.

Read moreBare Earth is bringing a touch of South Africa to the UK.

Read moreThe Essarts poultry plant in France has resolved its problem of frost condensation and water droplets by drying the air.

Read moreMunters has announced it signed a definitive agreement to acquire HB Group, an international company that specialises in customised hygienic climate control systems for the food/dairy industries.

Read moreMunters' innovative rotor design is constantly ongoing and improvements in the structure of the rotor, the absorbents and design allow an energy efficient dehumidification process.

Read moreThe new Munters Quantum™ desiccant wheel rotor is a further refinement of the company’s high-performance silica gel (HPS) rotor, which is at the heart of most Munters dehumidifiers.

Read moreKitchen Range Foods has been producing sweet and savoury frozen food products for more than 30 years. Part of the International Marfrig Group, it supplies products to big-brand food outlets, as well as national and regional food wholesalers.

Read moreRegional Offices

Matriz Curitiba Rua Anselmo de Limo Filho, 343-C

CEP: 81 290-250 CIC Curitiba

Brazil

No 12 Yu Hua Road

Industrial Zone Area B

Tianzhu Airport

Beijing 101300

China

Air Treatment

Slevacská 2368/ 68

CZ-615 00 BRNO

Czech Republic

272, Funado 3chome

Itabashiki, Tokyo 1740041

Japan

Av. Milenium No. 5000

Fracc. Parque Industrial Milenium

NL CP 66000

Apodaca

Mexico

PO Box 229

NL2400 AE Alphen a/d Rijn

Netherlands

No 6 Genting Road

Hex 0400

349471

Jubilee Industrial Estate

Singapore

22 Angus Crescent Longmeadow Bussiness Estate

Edenvale 1610 Gauteng

South Africa

Daeha B/D 808 14-11 Yeouido-dong Yeongdeungpo-ku

150-715 Seoul

South Korea

C/Playa de Liencres no 2

Europa Empresarial, ED Londres

E28230 Las Matas Madrid

Spain

Zweigniederlassung Effretikon

Im Langhag 11

CH-8307 Effretikon

Switzerland

Air Treatment

10 Ramsay Court, Hinchingbrooke Business Park

Huntingdon

PE29 6FY, Cambridgeshire

United Kingdom

121/107 RS Tower Bldg. 40th Fl.

Zone B Ratchadaphisek Rd., Dindaeng

10400

Bangkok

Thailand

AirT, SCC, AgHort

Atasehir Bulvari Gardenya Plaza 5 Kat: 6

34758 Atasehir

Istanbul

Turkey

Jebel Ali Free Zone

Warehouse DA02, DA03

PO Box 18467

Dubai

United Arab Emirates

PO Box 640

Amesbury, MA 01913

United States of America

Energieweg 69

NL-2404 HE Alphen a/d Rijn

Netherlands

Dehumidification and HumiCool

Unit A, OSIC Building, (Nguyen Hue St. District 1)

Ho Chi Minh City

Vietnam